scroll down for a customer success story ˅

Features:

- Automatic blade measurement

- Constant load monitoring

- Constant pressure monitoring

- Constant surface speed

- No material deformation

- Increased blade life

- Better yield loss

- Less cost per cut

Options:

- Hot or cold cutting

- Single or batch cutting

- Material measuring

- Complete material handling systems

- Automatic crop removal

- Coolant & mist collection systems

SPECIFICATIONS

Bar Section (Single cut or multiple cut)

Up to 12 inches single cut (305mm)

Wheel Diameter

Up to 48 inches (1219mm)

Surface Speed of Wheel

up to 20,000 SFPM (100 m/second)

Cutting Speed (average, depending on material)

Up to 1.5 inches square/second (9.6 cm square/second)

Feed Rate Control

Adaptive servo controlled with closed loop feedback

Cutting Temperature

Ambient to 1000 degrees F (ambient to 538 degrees C)

Motor Power (with automatic RPM regulation)

Up to 200 HP/ A/C VF (149KW)

Sequence Control

PLC (Programmable Logic Controller)

Saw Blade Speed Control

With automatic wheel-diameter-measuring; speed up control by PLC and A/C VF motor drive

COMPANY Houston, PAThe company produces titanium wire, shapes, medical devices and finished bar for the Aerospace, Medical, Consumer, Infrastructure. |

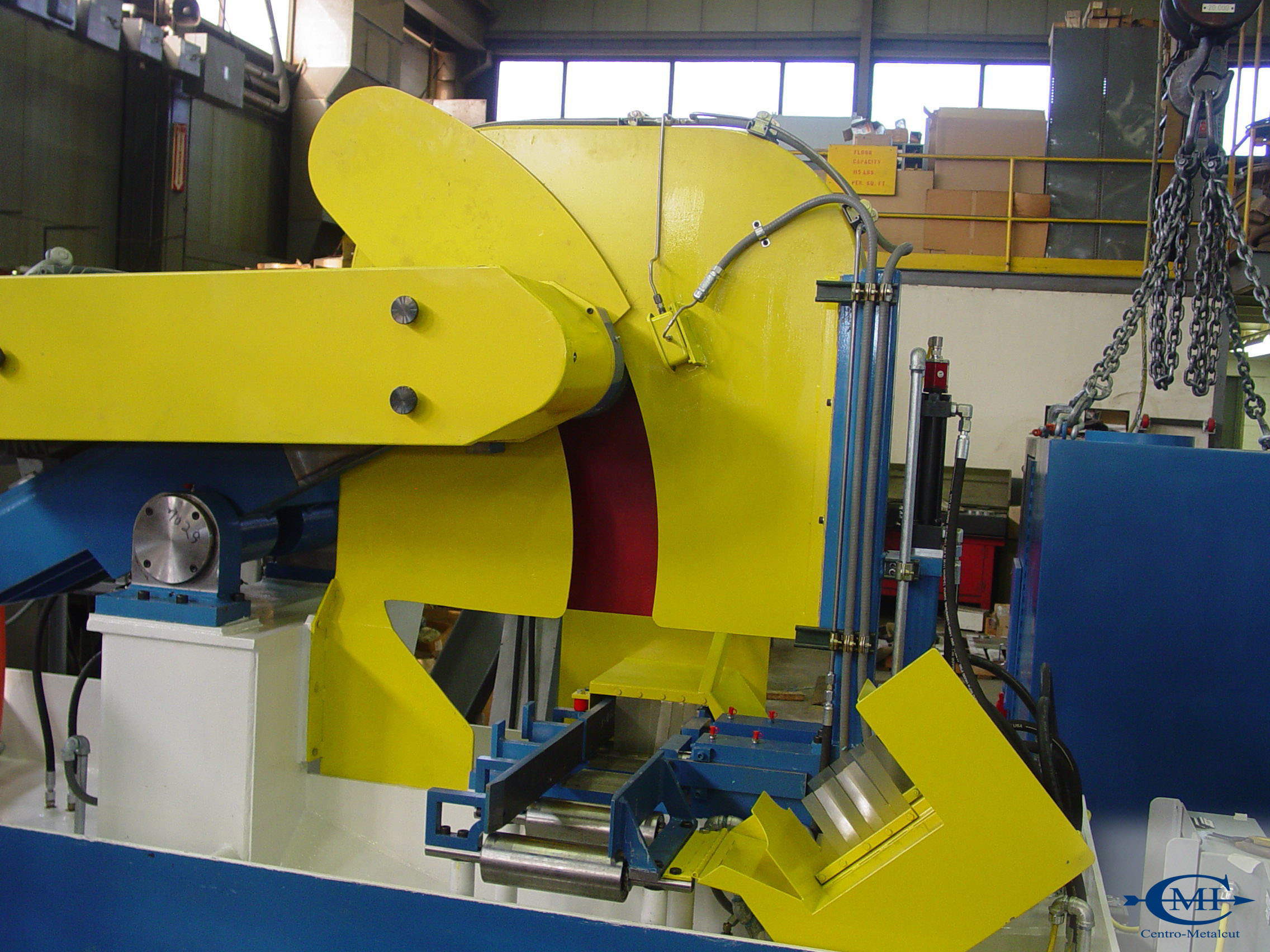

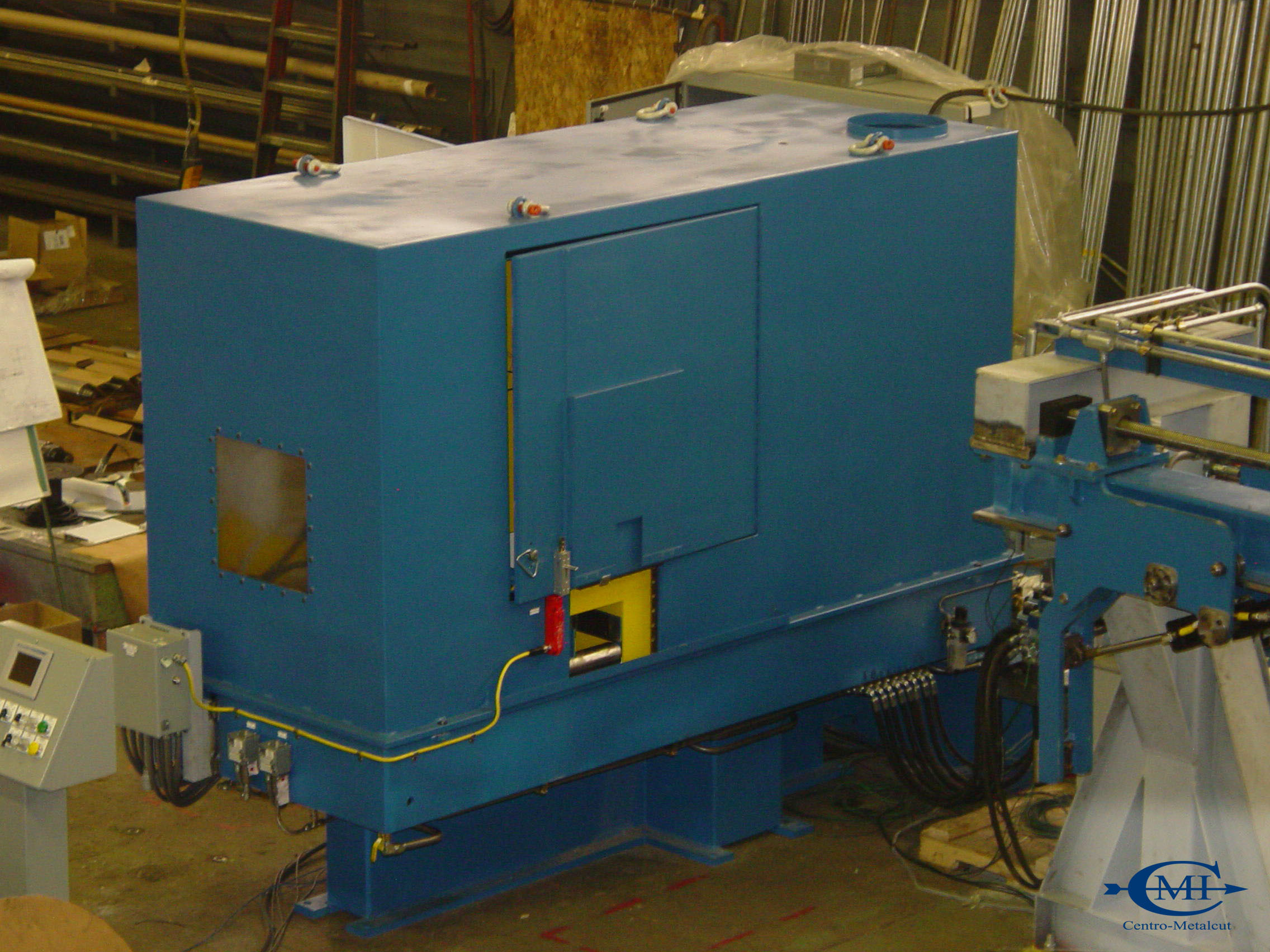

EQUIPMENT CAW 700/75HP SawCuts titanium round bars up to 3-1/4” OD, temperatures up to 400°F. 75HP, 34” cutoff blade. |

FEATURES Coolant While CuttingA high pressure coolant nozzle that tracked the saw blade to ensure coolant was properly getting into the cut. Others use a flooding type system which doesn’t stay in the cut. |

APPLICATION

Benefits

The customer is cutting finished bar stock to be supplied directly to its customer. The customer currently didn’t have a way to cut finished bar product in this reversing rolling line. This allowed them to offer this product to their end customers which they currently weren’t able to offer. The saw allowed for efficient and accurate cutting of heat sensitive material. Centro-Metalcut also supplied a small in line measuring gauge to measure lengths of 8’ to 14’.